-

Why Purge?

Purging Compounds are an easy-to-use and affordable way to dramatically reduce scrap & downtime in plastics manufacturing. But how do you know if purging compounds are right for you?

Learn why purging compounds are so important and see how Asaclean® helps your entire team succeed.

Our Purging Experts answer frequently asked questions and address topics that benefit Process Technicians, Maintenance teams, Buyers, and even Plant Managers.

Purging 101

Our in-depth guide tells you everything you need to know about purging compounds. We want to give you the tools you need to make the best decision for your processing needs..

-

Cost Savings Solutions

Our singular focus is saving your facility save time and money.

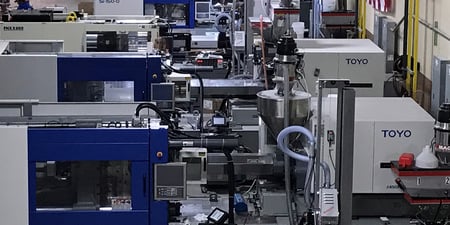

Asaclean® helps injection molders, extruders, and blow molders dramatically reduce scrap and downtime.

Whether you’re struggling with hot runner color changeovers, costly screw pulls, or holding a bubble in blown-film extrusion, we have the solution to your problems.Asaclean® Purging Compounds are engineered to tackle your hardest processing challenges and make an incredible difference in your process efficiency.

Here are some of the ways we can help you save:

-

Process and Industry

With over 2,000 current customers and a combined 200+ years of processing experience, we’ve seen it all. Asaclean® understands your priorities and has excellent cost savings solutions specific to your process and industry.

- Purging Products

-

Resources

Learn how processors at over 2,000 manufacturing locations in North and South America use Asaclean® to cut scrap rates, reduce downtime, and transform their process efficiency.

- About Us