Material degradation is a costly concern for all thermoplastic processors.

Contamination causes cause poor quality and scrap. This compromises appearance and structural integrity of the plastic part design. Today we will look at some causes of degradation at start-up.

1.) Excessive residence time

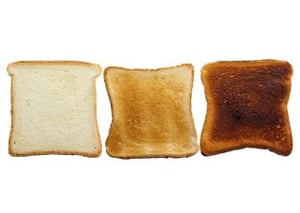

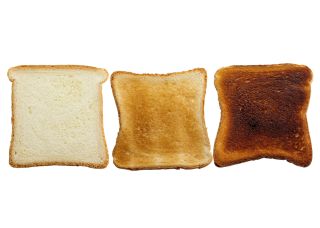

Excessive residence time is a leading cause for thermoplastic degradation. The longer your pellets reside within the machine, the better the chance they will start to burn. This is no different than leaving your toast in the toaster for too long.

2.) Location and duration of heats

When considering how degradation occurs, many processors overlook when and where heat is being applied at start-up. It is important for all processors to understand the amount of heat energy and time needed for each zone or area of the processing machinery to reach temperature. More steel will require more time and energy to get to the desired process temperature set-point.

It will take much longer for the screw and barrel to reach process temperature than the nozzle and end cap area on an injection molding machine. Similarly, on an extruder, the adaptor tooling or auxiliary components will take generally take less to heat than what is required for the extruder barrel and any large dies.

3.) Do NOT set it and forget it

I often see processors turn on all heaters at once with the setting at the desired process temperature and walk away to begin startup of the next machine. Inevitably this can lead to material degradation. Any heat sensitive residual or production materials located within areas of less steel are likely to be exposed to an excessive amount of residence time in this scenario.

4.) Seal with purge when shutting down

To counter these issues, implement good practices at the shutdown. First, I recommend you purge out any heat sensitive resins. Next, seal all areas of the machinery with a commercial purging compound. Purging compounds are generally made with more forgiving or heat stable carrier resins, such as styrene or olefins. Implementing a purge program for sealing prior to shutdowns ensures a clean machine.

5.) Identify & bank the heats in areas of less steel at start-up

Identify and bank the heats in these areas of less steel. How to do so is dependent on the type and program-ability of the heat controller being used. It is also possible to do this manually by entering set points. Use a lower initial temperature than the other areas of the machine that take longer. Another option is adding in a time delay with a two-step temperature setting if the heat controller allows.

Upon start-up, it is important for the processor to consider the effect of excess residence time at each area of the machine being heated. Doing so will provide a much faster and defect free start-ups.

If you would like additional information and some useful tips on maintaining machinery and best practice purging methods, please contact your Asaclean Technical Sales Representative.

Learn about the importance of implementing proper purging procedures by downloading this free industry guide.

Comments